Why Investment Casting ?

- Investment casting process gives smooth surface finish (Between 3 Ra To 6 Ra) comparative to sand castings, forging & other processes.

- Very complex castings can produce without any ceramic core. Less machining stock require comparatively sand castings.

- All popular metal alloys can be poured in the investment process with highest tolerance controls.

- Machining cost can reduce by investment casting process.

Company Quality Management System

Investment Casting Process

Die /Tool Design & Development

Die /Tool Design & Development

Design & develop Die from client provided drawing /3D model by CNC & VMC machines.

Wax Injection

Wax Injection

Wax pattern produce by wax injection. Melting wax inject as per standard parameters and after holding wax pattern remove from die.

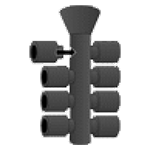

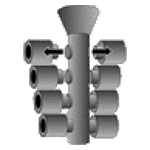

Assembly

Assembly

The patterns are attached to a central wax stick, called a sprue (Cup) & Runner, to form a casting cluster or assembly.

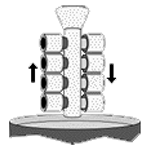

Ceramic Coating

Ceramic Coating

The built by immersing the assembly in a liquid ceramic slurry and then Process Investment Cast Mfg & Exporter Of All Types Of Investment Casting into a bed of extremely fine sand. Up to eight layers may be applied in this manner.

De-waxing

De-waxing

Once the ceramic is dry, the wax is melted out, creating a negative impression of the assembly within the shell.

Melting & Pouring

Melting & Pouring

In the conventional process, the shell is filled with molten metal by gravity pouring. As the metal cools, the parts and gates, sprue and pouring cup become one solid casting.

Knockout

Knockout

When the metal has cooled and solidified, the ceramic shell is broken off by vibration or knock-out machine.

Cut Off & Fettling

Cut Off & Fettling

The parts are cut away from the central sprue using a high speed friction saw / gas Cutting or Arc Cutting. After cutting casting finish with pneumatic tools. Also finish with blasting process, e.g Sand blasting /Shot Blasting as per customer requirements.

Finished Castings

Finished Castings

After Visual & Dimensional inspection castings are ready for shipment to the customer.